FAT APPLICATION TANKS AND SYSTEMS

For use with Animal Grease, Tallow, Molasses, Blends, & Liquid Feeds

Heated Storage Tanks

- Commercial

- Industrial

- Agricultural

- Bulk Storage

- Portable

Standard Sizes

- 2,000 Gallon

- 7,000 Gallon

- 10,000 Gallon

- 15,000 Gallon

- Custom Sizes Available

Standard Tanks Listed Above are Equipped with:

- 25 GPM Positive Displacement Pump

- 2″ Inlet Basket Strainer

- 2′ X 3′ Access Door

- UL Listed Electrical Disconnect and Controls

- Pressure/Bypass Tank Recirculation

- 6,000 Watt Electric/Glycol Heater

- Internal Vent/Overflow

- Ladder and/or Fall Restraint

- Top Inspection Manway

Piping

- Black, Stainless Steel, and Teflon

- Up to 600 degree temperature range

- 1,000 PSI rating

- Quick installation time

- Durable

- Longer life

- Low/No maintenance

- Product line pipe size available from 3/4″ to 2″ for a wide cariety of application rates

Options and Equipment

- Batch meter readout

- Stainless steel valves

- Carbon steel valves

- Line set assembly

- Nozzle assembly

- Stainless steel braided teflon tubing

- Liquid level inventory

- Electric actuators

- Low temp indicators

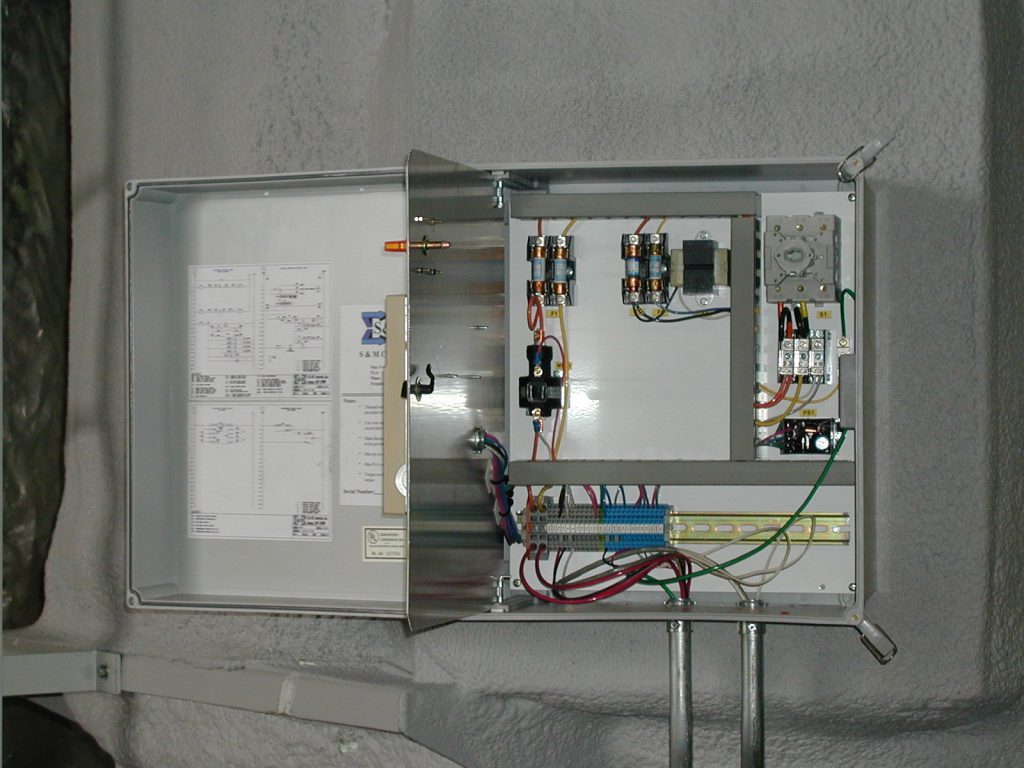

Controls

All of our tanks contain a standard control and electrical package which eliminates the need for costly field wiring. The electrical components are housed in a plastic weather proof enclosure to prevent moisture and to eliminate corrosion.

Components of Panel

- UL listed parts and enclosure

- Digital temperature control and monitoring

- Circuit fusing and distribution

- Motor contactors

- Valve relays

- Meter power supplies

- Wiring diagrams

UL listed Equipment

Heating and Pumping Module

The heart of our system consists of a module that we developed to reduce cost and production time on out tanks, while at the same time increasing the reliability. The result was a compact heating system built into the bottom of the tank. The heater itself provides the mounting base for all the components under the tank- from the pumps, to the electrical switches and lights. This allows for easy access to the components and quick assembly or disassembly if needed.

Features

- 4,500 – 6,000 watt heating system

- Components accessible from door

- All equipment is suspended

- Service light and outlet

- Thermostat safety limits

- Standard parts and elements

- Easy maintenance and service

- Bottom fill

- Bottom drain

- Expansion tank

- Pressure gauge

- Water circulation pump

- Water blowoff

- Service disconnects on pumps

- Stainless steel valving